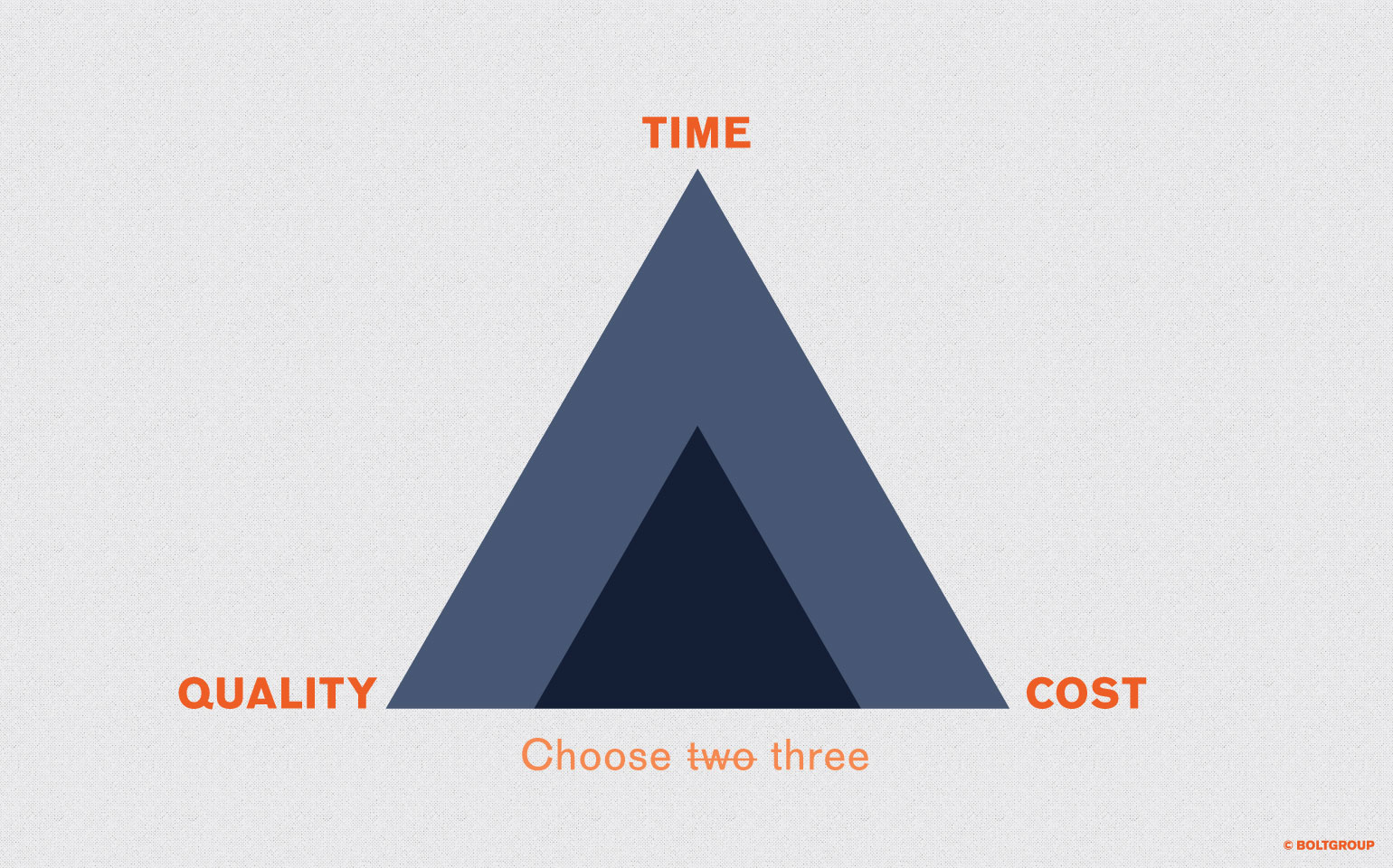

We’ve all heard it. “Good-Fast-Cheap. Choose Any Two.” The symbol above used to hang over the shop manager’s office at my first job and was doctrine in the engineering office. But that was then.

June 21st, 2016

How Digital Design Tools Let You Have It All

Today, the prevalence of new digital product development tools is turning the triangle on its head.

Here are three tools that, used well, have changed the playing field:

- CAD and PLM

Although CAD and PLM systems aren’t brand new technology, they’re impacting the triangle. These tools allow designers and engineers to create and share virtual designs much more quickly than before. [Time and cost savings.] Ideas developed with CAD and PLM are shared with others earlier in the design process. This increases opportunities for collaboration, review, and improvement that enhance product differentiation and value for customers. [Quality improvement.] Parametric CAD programs allow engineers and designers to easily make iterative design changes as new information and requirements arise. [Time and cost savings.] These changes can then be fed throughout the development process so concurrent design work employs the most up-to-date data. - FEA/CAE

Finite Element Analysis (FEA), the most common tool in Computer Aided Engineering (CAE), affects all three points of the triangle. Traditionally we had to build time-intensive physical prototypes to validate designs and configurations. With FEA, designs are virtually validated, reducing the number of prototypes needed to take a product from concept to production. [Time and cost savings.]FEA streamlines engineering calculations on complex products or those with highly varied configurations. Development time is quicker and issues are tagged earlier, improving confidence at transfer to production. [Time savings. Quality improvement.]

Lastly, FEA provides vital engineering information during the design process to optimize designs, improve quality, and reduce the time and money spent making changes during preproduction. [Time and cost savings. Quality improvement.]

- Rapid Prototyping (RP)

Quick prototypes can easily save time and money, as well as improving quality—the whole triangle. Less time per prototype means more prototypes during a development cycle, and more opportunities to address issues and test features. [Quality improvement.] It also allows for easy integration of discoveries during early stages of the design process. Early prototypes let us get product ideas in front of end users and identify issues early, reducing costly and time-gobbling iterative design changes. [Time and cost savings.]Since RP allows assemblies to be tested and flaws addressed, the likelihood of costly production issues is reduced. [Cost savings.] Additionally, RP processes can produce parts with geometries that traditionally would require expensive setups and tooling. [Cost savings.]

Employing these three digital tools well can set the product development triangle spinning. So, go ahead, pick any three.