Manufacturers are constantly looking for ways to improve product quality, improve product cost, improve speed to market, and develop innovative technologies that give them a competitive advantage.

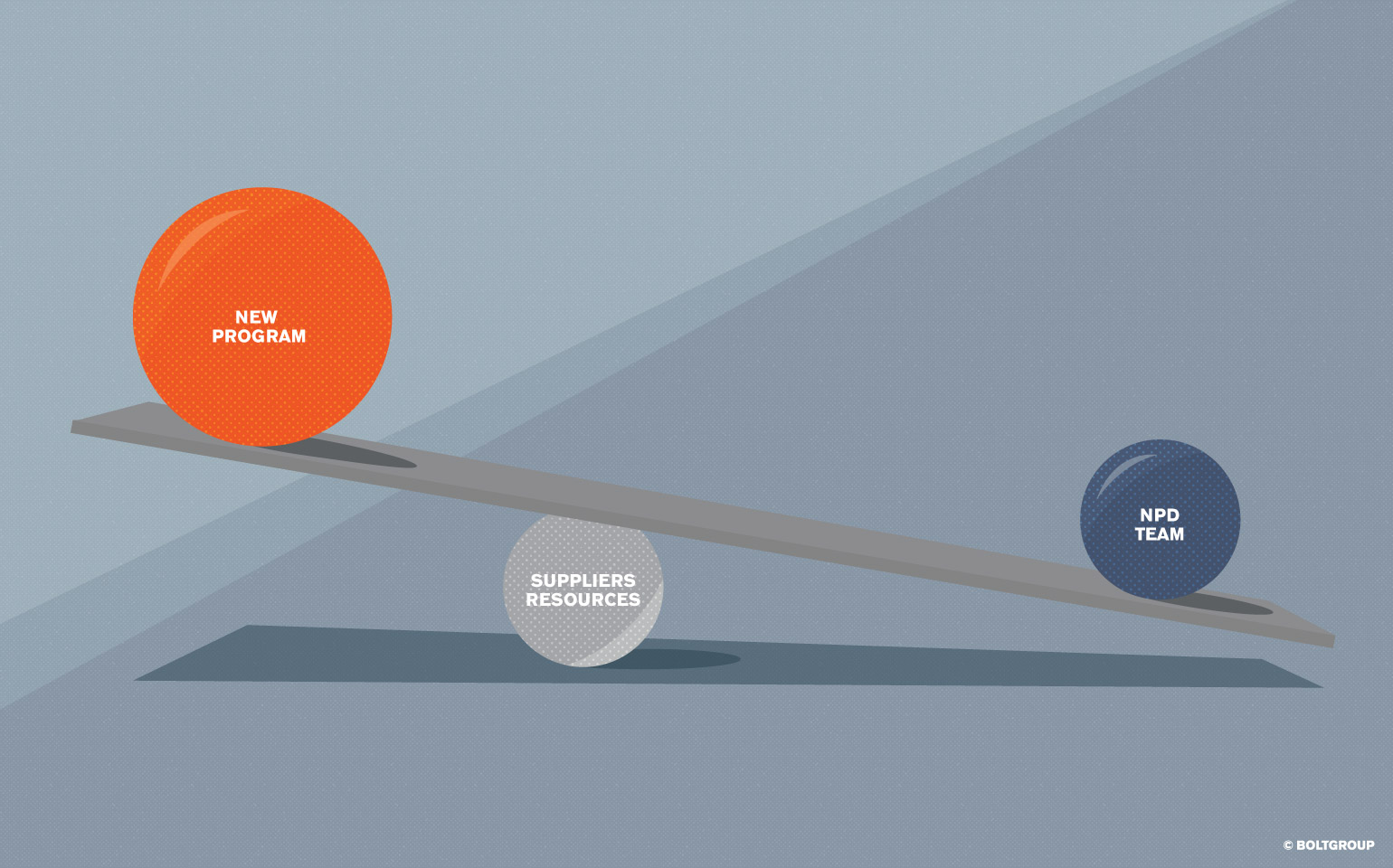

An important trend is to take advantage of your key suppliers as a strategic resource for your NPD team. Success depends on these fundamental factors:

- Choosing the right supplier.

- Deciding when and where to involve a supplier in the NPD process. This can range from “make it to spec” to providing the entire design of a component or sub-assembly.

- Making a commitment to this approach at the top of both companies.

- Establishing and maintaining open and free communication between the companies.

4 Ways Partnering with Suppliers has a Positive Impact:

1. Adds Valuable R&D to Your NPD

If you select suppliers not only on cost and quality, but also on technology leadership regarding your key components, you expand R&D for your project. Look first at your strategic business priorities. By developing a close and open relationship based on trust, you will benefit by access to the supplier’s back room R&D. You can tap into what they see as the future in this key technology and get a preview that offers an advantage over your competition.

2. Expands Your NPD Team

You’ll have greater success when your supplier is an active participant on your project team. While the supplier representative doesn’t need to be in every team meeting, they do need to be kept in the loop with all decisions affecting their area of involvement. Some suppliers will even be willing to co-locate design engineering personnel. After qualifying a supplier’s design, engineering, and communication capability, expect valuable contributions regarding improved design solutions, as well as improved design for manufacturing.

3. Speeds up the NPD Team

This can be doubly true when using offshore suppliers. Your team can work on a problem all day, then send any issues and questions to the offshore supplier, and have answers and new progress in the morning. A 24-hour development team! This kind of involvement also gives your supplier a head start on preparing for production.

4. Improves Cost Control

Utilizing your supplier’s technical team can save (or defer) engineering manpower, equipment costs, prototyping costs, and testing.

It’s important to involve your supplier as early as possible in the NPD process. Eighty percent of the total product costs get “locked in” during the early development phases of concept and design engineering.

Companies that involve suppliers early in the NPD process (bringing their product and process expertise) are seeing improvements in product cost and quality and in overall speed to market.

Having outlined the positive impact of involving suppliers, I also must caution against allowing your supplier to provide the entire product. Over the past decade, it became popular for U.S. brands to develop specifications for a new product and then source it out to an offshore supplier. In many cases, the U.S. company loses leverage, ownership of important IP, and potentially the supplier becomes the competition. This is very common among Big Box suppliers.

Building great supplier relationships takes an investment in time and a willingness to communicate openly and freely. It must be supported by the top management of both organizations. However, this commitment can bring a competitive advantage to NPD when handled well.