dematic

Automated Guided Vehicles: Modular Design VBL

Through the principles of Design Innovation and Design for Manufacture (DFM) BOLTGROUP worked with Dematic to develop a modular family of autonomous vehicles with longer product life and improved serviceability, plus a 25% reduction in manufacturing costs thanks to improved manufacturing efficiencies.What We Did

Industrial Design

User Research

Visual Brand Language

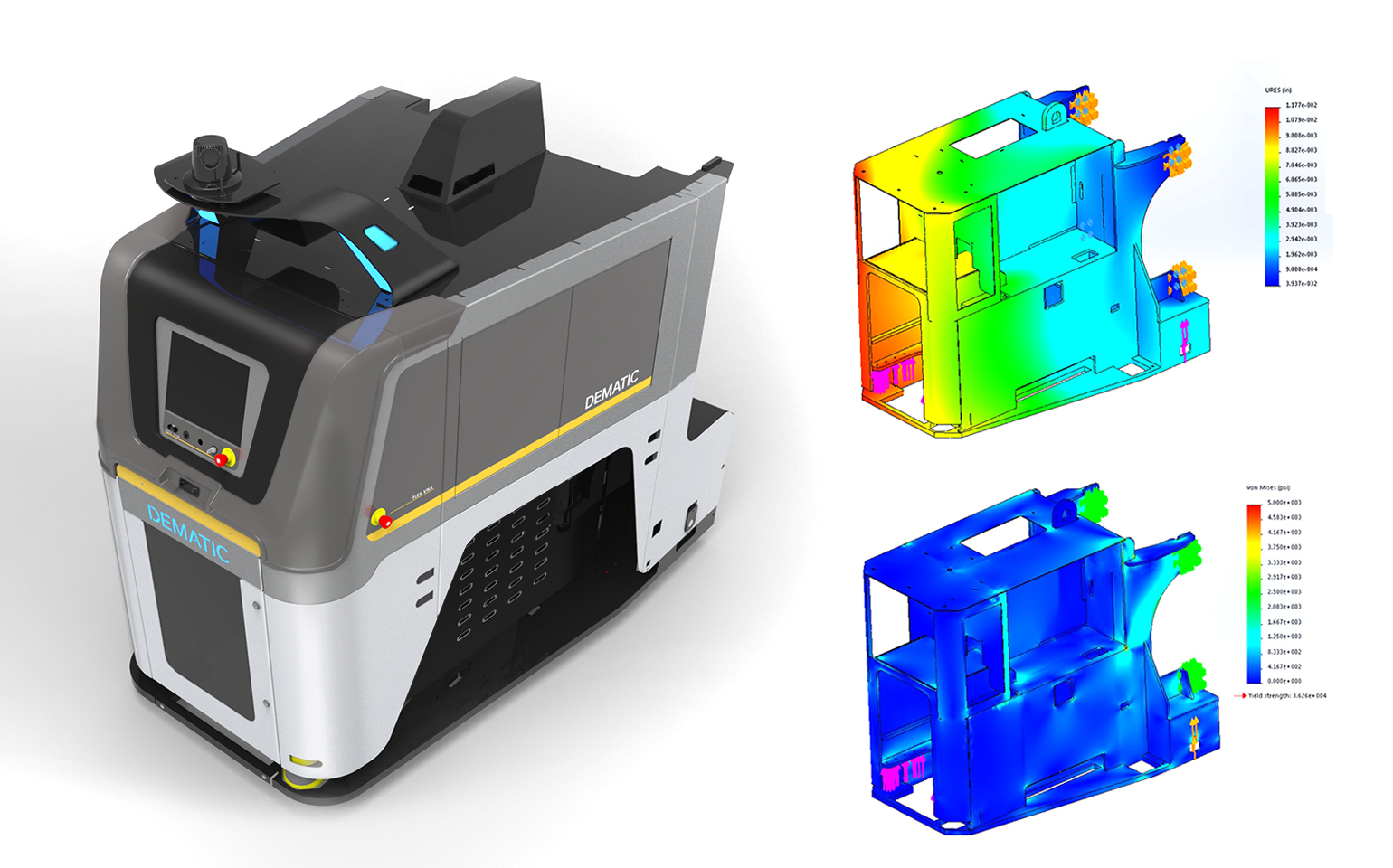

Mechanical Engineering

Manufacturing Support

Finite Element Analysis (FEA)

Prototyping

3D CAD Modeling

Production Part Documentation + BOMs

Design for Sustainability

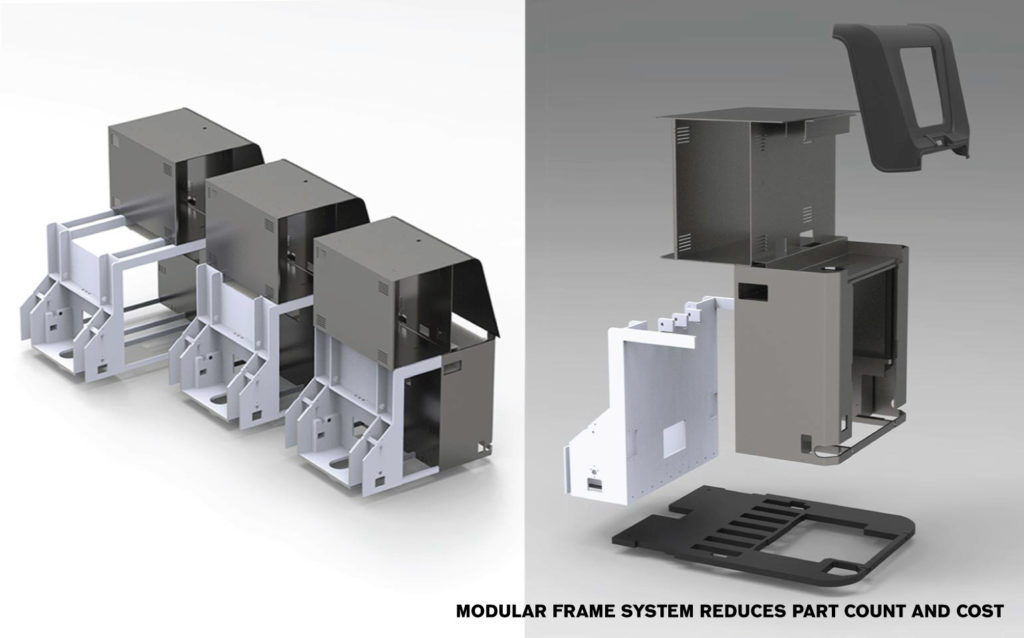

Modular Design

Design for Efficiency

Design for Life Cycle

Challenge

Dematic came to us as a leader in the rapidly evolving technology of automated guided vehicles (AGVs). Their advanced warehouse guidance technology was state-of-the-art, backed by an outstanding reputation for quality and a loyal customer base. It was time to update and modernize their vehicle designs to respond to customer demand for more energy efficient, faster, and nimbler vehicles capable of navigating narrower aisles and tighter warehouses. They were also facing competition from lower priced competitors, pressuring them to find ways to reduce costs and increase value.

Dematic wanted to introduce a modular platform with improved manufacturing costs, a more intuitive human / machine interface, and better access for repairability. They also wanted the vehicles to have a sophisticated, advanced aesthetic that matched their technological capability.

Solution

BOLTGROUP engineered a modular frame / chassis design with slot-and-tab construction that combines like LEGOs for faster and easier assembly with less welding. By optimizing the chassis geometry, engineers were able to reduce weight, resulting in more nimble handling without any reduction in load handling capacity.

By focusing on stakeholders’ “jobs to be done”, designers were able to make ergonomic improvements for faster vehicle service and maintenance. BOLTGROUP engineered a multi-layered lift gate door for quick access to electronics with generous wire way access. The exterior metal and plastic body panels established a unified Visual Brand Language (VBL) on products ranging from 200 ft cranes to toaster-size omnidrive robot bases.

Result

The new design cost 25% less per vehicle to manufacture than its predecessor. With significantly reduced welding time, Dematic saw major reductions in labor cost, power consumed, and carbon emitted. The products are made in the US, and the supply chain was carefully considered for transportation and manufacture efficiency. So far, the reception has been exceptional, with new AGV sales outperforming expectations since the product launch.

For more insights on sustainable design, head over to our Sustainability Resource Portal.